Development

Product

Product

A Cross-field Agile Development Team consisting of Chinese and Western Cuisine Chefs, Food Science, and Project Management

With the original intention seeking for health and delicacy, Sing-Lin Foods Corporation aims not only to provide consumers with fine cuisine experiences as well as tasty foods, but also to realize the best natural and authentic raw materials in terms of selection and allocation as we could. When a new product is developed from the flavor design and development process, the agile project management is applied to integrate raw material supply chain, kitchen, food safety, market research, production process, quality control, purchasing management, and finance management team. By forming such a development management team emphasizing quality, safety and meeting with consumers’ needs and expectation, we wish to provide you with the best food we could offer.

With the original intention seeking for health and delicacy, Sing-Lin Foods Corporation aims not only to provide consumers with fine cuisine experiences as well as tasty foods, but also to realize the best natural and authentic raw materials in terms of selection and allocation as we could. When a new product is developed from the flavor design and development process, the agile project management is applied to integrate raw material supply chain, kitchen, food safety, market research, production process, quality control, purchasing management, and finance management team. By forming such a development management team emphasizing quality, safety and meeting with consumers’ needs and expectation, we wish to provide you with the best food we could offer.

Product Development

A Cross-field Agile Development Team consisting of Chinese and Western Cuisine Chefs, Food Science, and Project Management

With the original intention seeking for health and delicacy, Sing-Lin Foods Corporation aims not only to provide consumers with fine cuisine experiences as well as tasty foods, but also to realize the best natural and authentic raw materials in terms of selection and allocation as we could. When a new product is developed from the flavor design and development process, the agile project management is applied to integrate raw material supply chain, kitchen, food safety, market research, production process, quality control, purchasing management, and finance management team. By forming such a development management team emphasizing quality, safety and meeting with consumers’ needs and expectation, we wish to provide you with the best food we could offer.

With the original intention seeking for health and delicacy, Sing-Lin Foods Corporation aims not only to provide consumers with fine cuisine experiences as well as tasty foods, but also to realize the best natural and authentic raw materials in terms of selection and allocation as we could. When a new product is developed from the flavor design and development process, the agile project management is applied to integrate raw material supply chain, kitchen, food safety, market research, production process, quality control, purchasing management, and finance management team. By forming such a development management team emphasizing quality, safety and meeting with consumers’ needs and expectation, we wish to provide you with the best food we could offer.

Moreover, Sing-Lin Foods Corporation started as noodle manufacturing specialist, we always strive for excellency in all noodle products. Now our technique development team implements AI technologies and process sensor modules for testing. By this new technological force, we expand from natural raw material formula combinations into wider collection and adjustment of production process parameters. Therefore, we could design all kinds of formulas, noodle forms, and product types with more creativities and ideas for the best textures.

Manufacturing Process

Mixing

Aging

Compounding

Drying

Slitting

Bundling

Mixing

Compounding

Water & Folding

Steam

Slitting

Drying

Bundling

RAMEN

NOODLE

Manufacturing

Process

Process

NOODLE

RAMEN

Mixing

Aging

Compounding

Drying

Slitting

Bundling

1/6

Mixing

Compounding

Water & Folding

Steam

Slitting

Drying

Bundling

1/7

During manufacturing, entrance and exit of raw materials in each shipment require specified temperature preservation and production process monitoring.

We have annual evaluation and factory-visit audition toward each supplier in order to ensure the qualities of supplied products and provided services.

We have annual evaluation and factory-visit audition toward each supplier in order to ensure the qualities of supplied products and provided services.

It’s Our Mission and Responsibility to be Selective with Suppliers of Raw Materials for Clients and Costumers

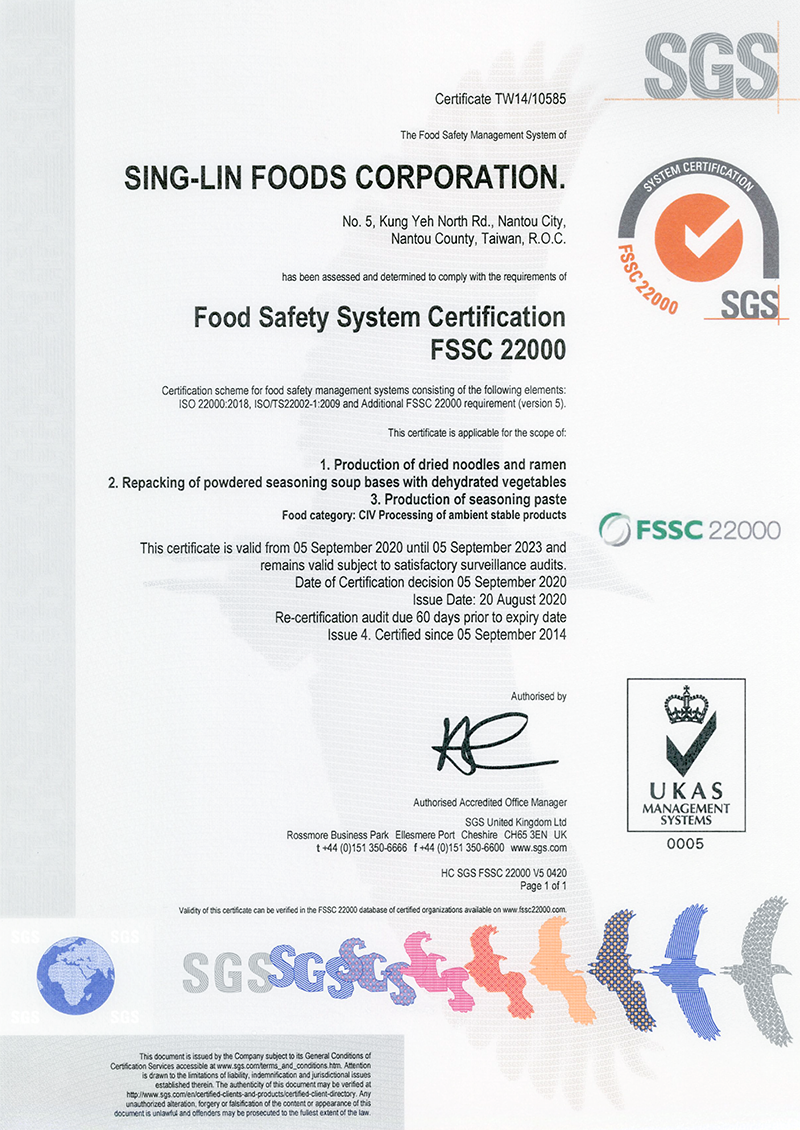

Over 95% of raw materials supplied to Sing-Lin Foods Corporation come from ISO22000-certified suppliers.

Sing-Lin Foods Corporation has its exclusive food safety division taking charges of updated global law and compliances of food safety and quality. Ever since a product development project is initiated, each of all raw materials is finely selected in accordance with the establishment of a quality specification.

Every shipment of raw materials needs to be processed in SOP.

Sing-Lin Foods Corporation has its exclusive food safety division taking charges of updated global law and compliances of food safety and quality. Ever since a product development project is initiated, each of all raw materials is finely selected in accordance with the establishment of a quality specification.

Every shipment of raw materials needs to be processed in SOP.

It’s Our Mission and Responsibility to be Selective with Suppliers of Raw Materials for Clients and Costumers

Over 95% of raw materials supplied to Sing-Lin Foods Corporation come from ISO22000-certified suppliers.

Sing-Lin Foods Corporation has its exclusive food safety division taking charges of updated global law and compliances of food safety and quality. Ever since a product development project is initiated, each of all raw materials is finely selected in accordance with the establishment of a quality specification.

Every shipment of raw materials needs to be processed in SOP.

Sing-Lin Foods Corporation has its exclusive food safety division taking charges of updated global law and compliances of food safety and quality. Ever since a product development project is initiated, each of all raw materials is finely selected in accordance with the establishment of a quality specification.

Every shipment of raw materials needs to be processed in SOP.

During manufacturing, entrance and exit of raw materials in each shipment require specified temperature preservation and production process monitoring.

We have annual evaluation and factory-visit audition toward each supplier in order to ensure the qualities of supplied products and provided services.

We have annual evaluation and factory-visit audition toward each supplier in order to ensure the qualities of supplied products and provided services.